How Membrane Switches Ensure High-Performance and Efficiency in Electronics

How Membrane Switches Ensure High-Performance and Efficiency in Electronics

Blog Article

Membrane Layer Change Technology: The Trick to Trustworthy and Cost-Effective Interfaces

Membrane button innovation has actually emerged as a pivotal part in the style of user interfaces, offering both dependability and cost-effectiveness throughout a diverse array of applications. As we check out the diverse benefits of membrane switches, their potential for technology elevates concerns regarding future applications and advancing trends.

Recognizing Membrane Switch Technology

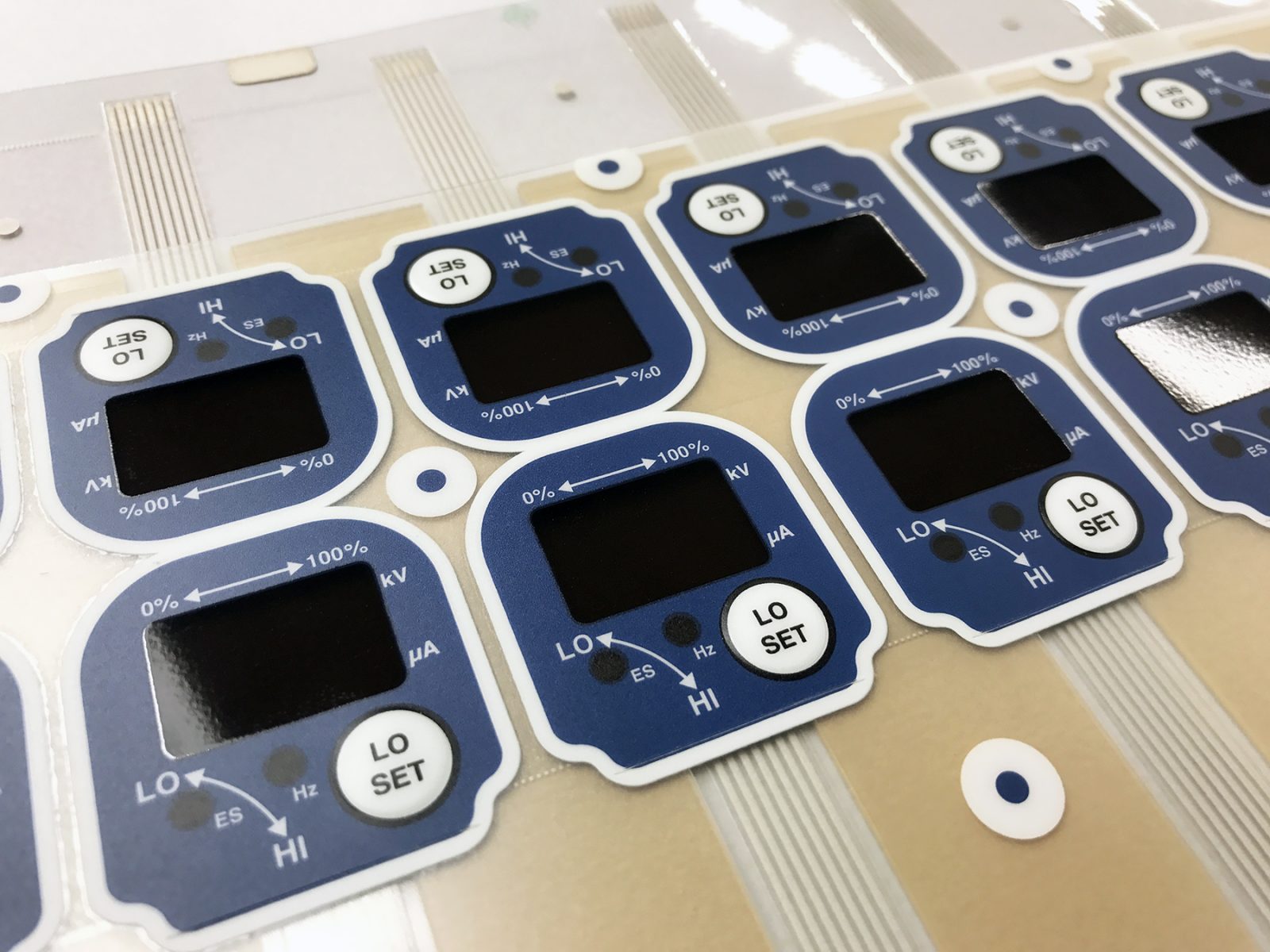

Membrane layer switch technology is a commonly used user interface option in different electronic gadgets, supplying a seamless blend of performance and layout. This innovation integrates numerous layers of materials, typically containing a graphic overlay, spacer layer, and a circuit layer. The graphic overlay shows the interface elements, while the spacer layer separates the circuit layer from the overlay until a user activates a button.

When stress is applied to the overlay, the circuit layer finishes the electric circuit, sending a signal to the tool. This system enables different arrangements, including tactile responses and backlighting choices, enhancing customer interaction. Membrane switches are normally made using resilient products such as polyester or polycarbonate, guaranteeing durability and resistance to environmental factors like moisture and dirt.

The versatility of membrane layer changes allows their application in varied sectors, consisting of medical tools, customer electronics, and industrial controls. Their small style enables combination into space-constrained environments, offering an effective individual interface without jeopardizing visual charm. Understanding the intricacies of membrane button modern technology is essential for makers and developers seeking to produce dependable and effective human-machine user interfaces.

Trick Benefits of Membrane Layer Buttons

While different interface remedies exist, membrane layer changes offer unique benefits that make them a recommended option in numerous applications. One of the key benefits is their durability; membrane buttons are made to withstand harsh ecological conditions, including dampness, dust, and temperature level variations, making certain long-lasting efficiency. This durability significantly minimizes the need for frequent substitutes, consequently decreasing total upkeep prices.

Moreover, membrane buttons are light-weight and portable, making them ideal for applications where room is limited. Their low-profile layout adds to a streamlined appearance without compromising functionality.

Cost-effectiveness is also a notable advantage, as the manufacturing process for membrane switches has a tendency to be less costly contrasted to typical mechanical buttons. This cost, incorporated with their reliability and ease of installation, settings membrane switches as a practical option for a vast array of markets looking for effective and reliable interface.

Applications Throughout Numerous Industries

How do membrane switches adjust to the varied demands of different sectors? Membrane layer switch modern technology is progressively acknowledged for its convenience, making it suitable for a wide variety of applications across several industries.

In consumer electronics, membrane buttons give a compact service for push-button controls and home devices, enhancing individual experience via intuitive style. Additionally, my site the commercial industry leverages membrane buttons for equipment control board, gaining from their resistance to harsh settings, such as wetness and dust.

Military and aerospace applications also make use of membrane buttons for their integrity and ability to hold up against severe conditions, making sure operational effectiveness in vital situations. Furthermore, the food and beverage sector takes on these switches for automated systems, where hygiene and ease of operation are paramount. Ultimately, membrane buttons are tailored to satisfy the one-of-a-kind demands of each market, verifying their necessary role in modern-day technology interfaces

Layout and Modification Choices

In the realm of membrane button modern technology, style and personalization options play a crucial duty in boosting capability and user interaction. These switches can be customized to satisfy certain functional demands and aesthetic preferences, making them functional parts in various applications.

One of the primary modification options is the layout of the switch itself, which can be created to suit distinct customer interfaces and ergonomic considerations. By readjusting the form, dimension, and arrangement of buttons, suppliers can develop user-friendly designs that facilitate ease of usage. Furthermore, the incorporation of various shades and graphic overlays enables branding and enhanced visibility, guaranteeing that users can promptly recognize features.

In addition, membrane layer buttons can be engineered with different responsive feedback systems, such as raised switches or audible clicks, to boost the individual experience. visit this website Different products can also be picked for durability and ecological resistance, attending to factors such as moisture, temperature changes, and chemical direct exposure.

Eventually, the substantial layout and modification alternatives offered in membrane button innovation equip companies to produce tailored options that not just meet practical demands yet additionally straighten with their branding and operational demands.

Future Patterns in Membrane Switches

As membrane button modern technology continues to develop, future fads are progressively concentrated on enhancing customer experience and integrating sophisticated functionalities. One substantial pattern is the assimilation of touch-sensitive and capacitive modern technologies into conventional membrane layer buttons. This development enables for more intuitive interface, providing tactile comments while keeping a streamlined design.

An additional arising trend is using eco-friendly materials, driven by the expanding demand for lasting manufacturing techniques. Makers are seeking to reduce their carbon impact by utilizing recyclable substrates and low-impact inks, lining up with global sustainability objectives.

Additionally, the rise of the Internet of Points (IoT) is triggering the unification of smart attributes right into membrane layer switches. Boosted connectivity choices will allow devices to interact with each various other, enabling for seamless assimilation right into more comprehensive systems.

In addition, advancements in printing modern technologies, such as digital printing, are allowing for greater read here layout versatility and customization. This enables makers to generate intricate designs and vivid colors cost-effectively.

Final Thought

To conclude, membrane switch innovation stands for a vital technology in interface style, offering significant benefits in resilience, modification, and cost-effectiveness. Its extensive applicability across varied industries underscores its significance in modern technology. As improvements remain to arise, particularly in touch-sensitive user interfaces and lasting materials, the possibility for membrane layer switches to enhance customer experience and functionality remains promising. Continued exploration of this innovation will likely generate additionally renovations and broaden its extent in future applications.

Report this page